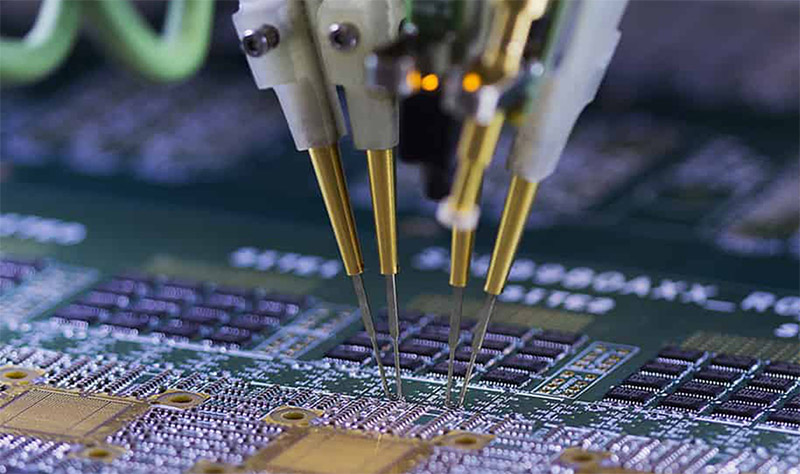

Capabilities of a PCB manufacturers or commonly called as PCB house specifies the technical aspects that every hobbyists or enthusiasts should look at. This will help us to understand whether the manufacturer can make our board as per specifications. In this article we are going to look at the capabilities of one of the biggest PCB manufacturer in China – PCBWay and why they are one of the best in PCB manufacturing.

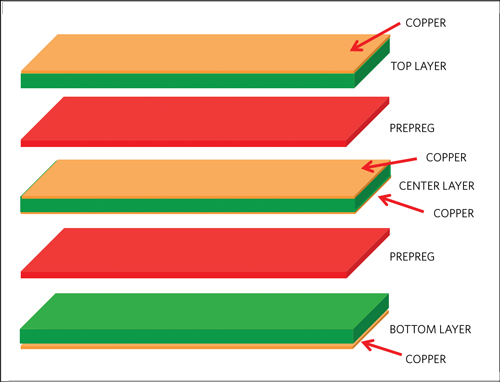

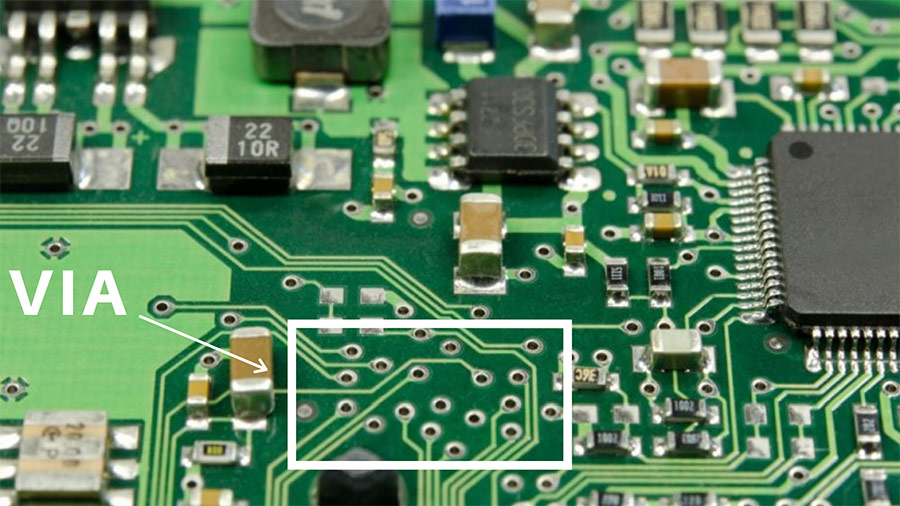

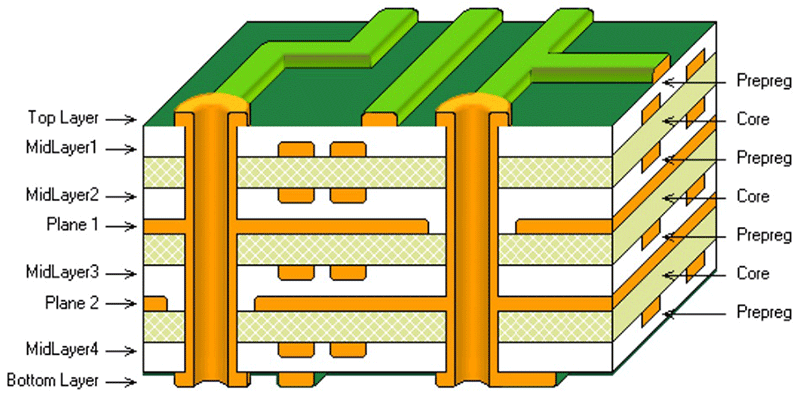

Number of Layers :

This is probably first and foremost thing that we will look at. PCB is made of sandwiched layers stacked on top of each other making the physical connection between components possible. More complex the board is more layers the PCB will be made of. PCBway is capable of making PCB of 1- 10 layers which means they are very well capable of building complex PCB boards. Most motherboards will of be of 8 layers and these guys can make much complex boards than mother boards.

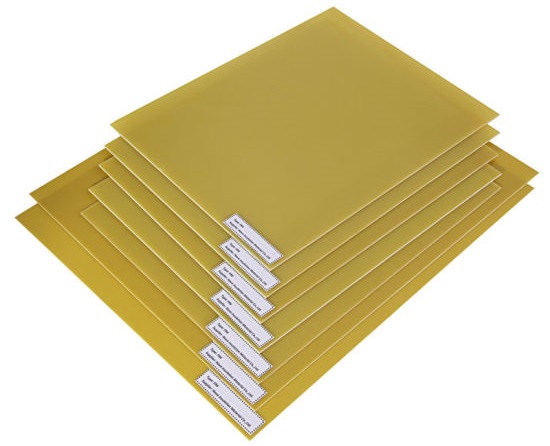

Type of material :

These folks make PCB boards out of two materials. FR-4 and Aluminium are two materials used to manufacture PCB boards. FR-4 is a glass reinforced epoxy laminate material over which a layer of copper is coated. Aluminium material is used when in need of high durability, light weight and have high heat dissipation.

Maximum PCB dimension :

This feature decides how big a PCB board can be. Large PCB boards are extremely important in power applications where we need large trace and enable good power dissipation. They are capable of producing boards that measure 500 x 1100 mm which is pretty large and mostly fit any application.

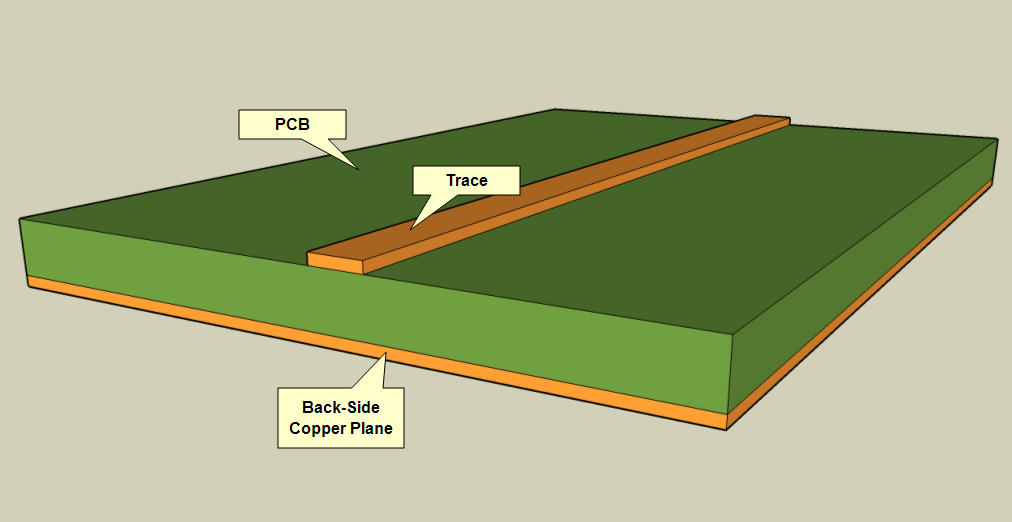

Minimum Trace width :

Trace width is a factor which decides the width the connection traces that run between components should be. Designers often go for lower trace width for accommodate large number of components in a board but things will get tricky for manufacturers to make boards with low trace width. Here PCBway is capable of manufacturing boards with minimum trace width of 0.1 mm / 4 mil which is pretty great especially when you are working with limited board space and SMD components.

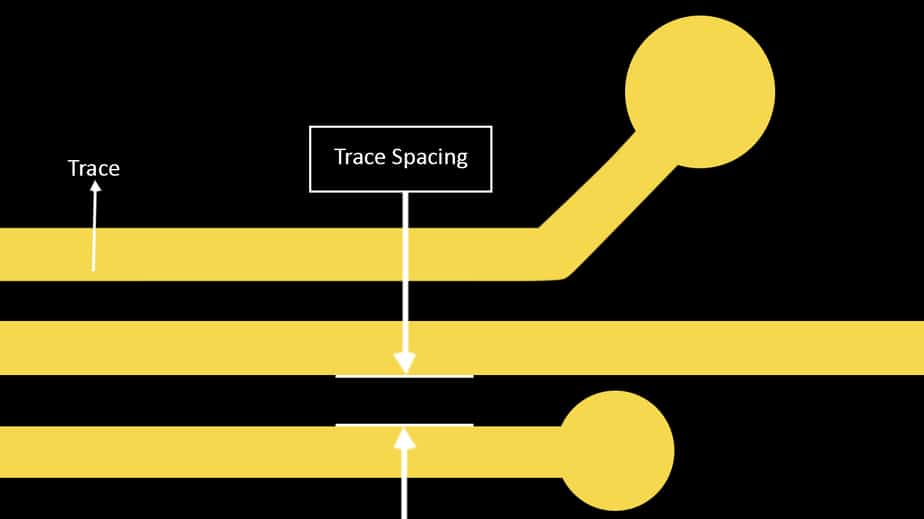

Minimum spacing :

Spacing refers to the space between component pads on the board. This feature should be used with caution by designers since we don’t want components to get into each others way which will create problem when assembling the board. Like trace width lesser the value of spacing trickier the manufacturing process will be. These guys can handle PCBs upto 0.1 mm / 6 mil of spacing.

Board thickness:

This characteristic denotes the range of thickness of the board they can manufacture. They can manufacture boards thickness of 0.2, 0.4, 0.6, 0.8, 1.0, 1.2, 1.6, 2.0 and 2.4mm.

Solder mask :

These are elements used in PCB manufacturing to prevent corrosion of Soldering joints and avoid shorting between traces running in the PCB boards. This Solder mask gives the unique green color to PCB’s. PCBWay can manufacture the boards using various Solder mask colors. They are Green, Yellow, Red, White, Blue and Black.

Check out their complete manufacturing capabilities in their website : PCBWay capabilities. In case if you want to manufacture PCB’s out of these specifications or different from their capabilities you can contact their sales representative.