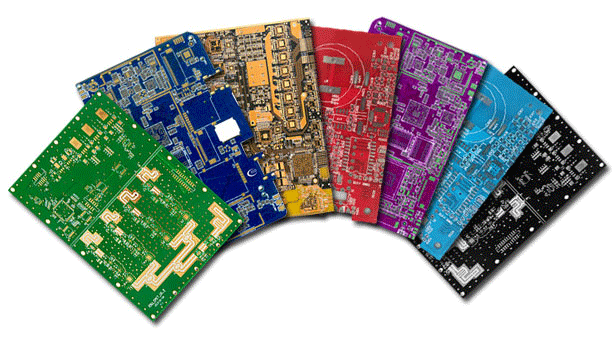

PCB fabricating is an essential process which constitutes the modern electronics. In order to choose the materials used for fabricating PCBs the functionality and application of the PCB should be considered. Some of the key factors such as electrical resistance, temperature resistance, flexibility, strength, mass, conductivity helps to decide the right material to build the PCB board. There are wide variety of PCB materials to choose from when coming to PCB substrates. In this article we will discuss few of those substrates and their importance.

What is PCB material or PCB substrate:

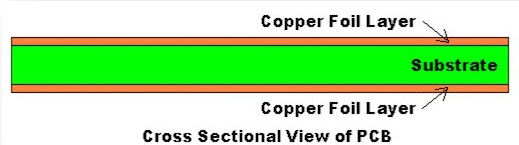

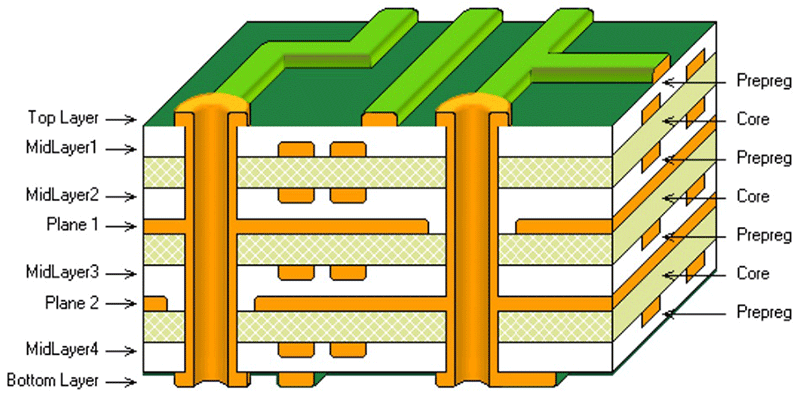

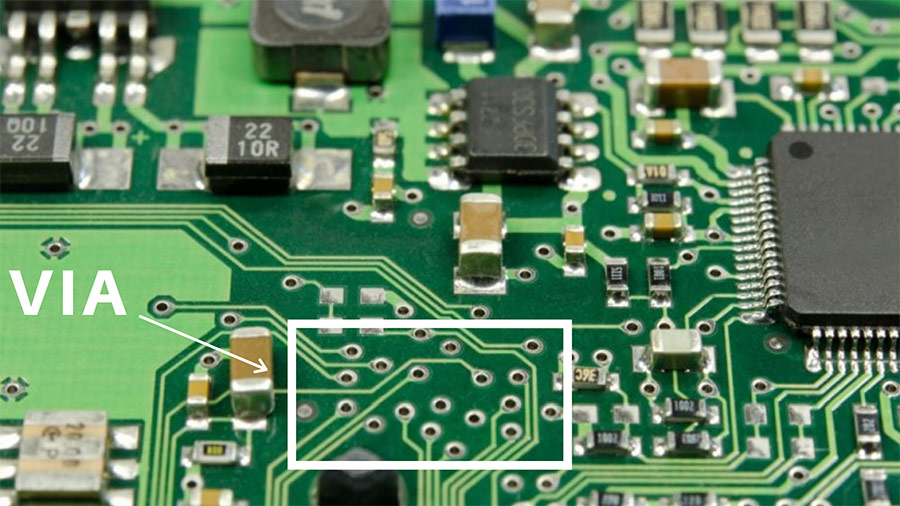

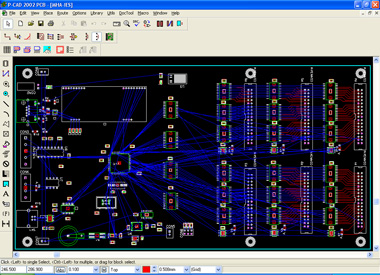

PCB boards are composed of different layers. These different layers are stacked together, heated and pressed to make the PCB we see in gadgets, computers, etc. A PCB material or substrate is the material on which other layers such as Copper ( for traces ), Soldermask, Silkscreen, etc, will be stacked upon. It acts as a foundation on which PCB traces are laid to establish connectivity. Another analogy to explain this better is to consider substrate as a canvas on which a painting will be painted. Learn more about PCB composition in this article. Often manufacturers specify the material using which the PCB will be built and its up to the user to choose the appropriate one.

FR-4 substrate:

FR stands for Flame retardant and it is made up of fiberglass and epoxy. It possess high mechanical strength and acts as a great insulator making it a great choice for PCB substrates. This FR-4 material is capable of withstanding hot and humid conditions well. This FR-4 substrate is most commonly used in PCBs due to it’s low cost and its versatile nature.

PTFE substrate:

This is also popularly known as Teflon PCB. This is made up of synthetic fluropolymer. Teflon PCBs are quite popular for its flexibility and high physical strength making it a great fit for applications such as wearable gadgets, machineries etc. These type of substrates are much preferred in RF and microwave applications due to their low dielectric constant which results in very less signal loss during transmission. This material is also lightweight in nature but possess high physical strength and resistant to high temperatures.

Metal substrate:

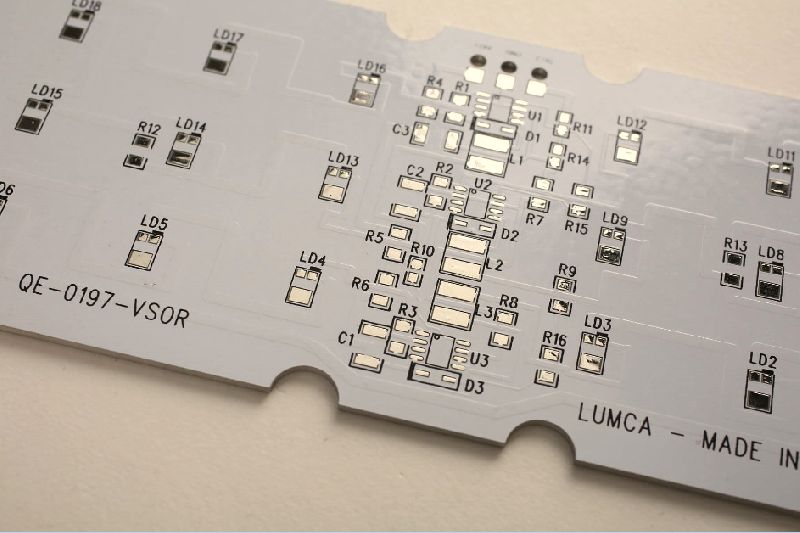

There are times which calls for the substrate to be metal. When heat dissipation in a PCB is extremely high other substrates cannot handle heat dissipation efficiently as Metal substrate does. Metals like Copper, Iron, Aluminum are commonly used metals when comes to substrate. Metal substrates tend to be heavy and expensive compared to other substrates.

These are the most common PCB substrate used to build modern PCBs. There are also other substrates such as CEM-1, RF-35, Polyimide etc.

Post your queries, comments and thoughts in the comments section below.