There are myriad of PCB manufacturers in the market and its very common as a customer to get confused in the process of picking the right one. If you have ever been in such situation or going through one right one, this guide may offer help to you. This article explains cutting edge PCBA machines manufacturers use to manufacture top quality PCBs at low price.

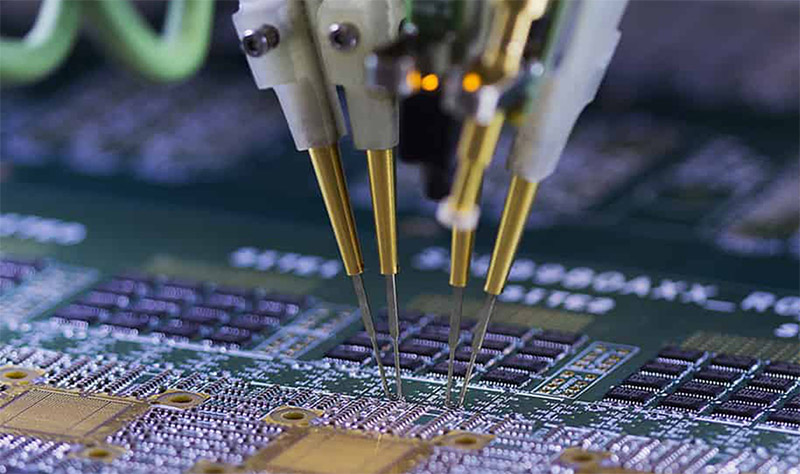

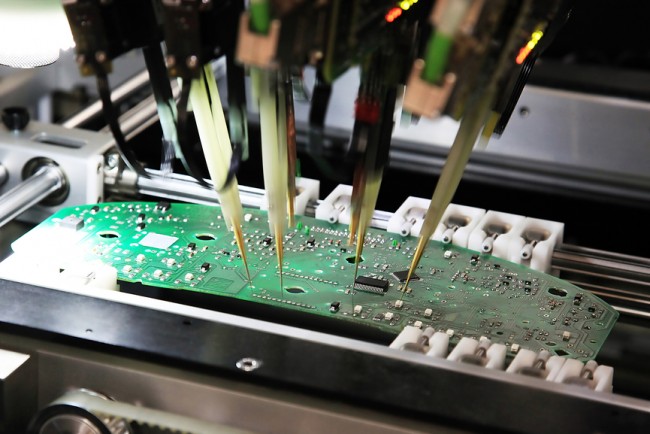

Yamaha Pick and Place machine:

This state of art machine from Yamaha automates the process of picking and placing the components in a PCB board. The PCB board which need to be assembled will be fed into the machine by means of a conveyor. A special known as Pick and Place file need to provided by the designer. This instructs pick and place machine to place the right component at the right spot in PCB. This machine will automatically pick the components from the component inventory and place them on the PCB board. This machine supports THT, SMD and components in other packages. Yamaha pick and place machine can handle 160 unique components for a PCB assembly in one instant.

See the working of pick and place machine

Wave soldering machine:

Wave soldering is the method used by PCB manufacturers to quickly solder the components to PCB. This also gives a high quality solder joint comparing to hand soldering. As a first step the boards will be placed in a conveyor inside the wave solder machine. Then solder flux in the form of mist will be sprayed on the surface of PCB boards. This is followed by heating of solder pads in the PCBs and components to bring it to optimum temperature for soldering. This is then followed by a wave of solder that comes in contact with the solder pads. The action of flux and heating will allow solder to occur at optimum level in right places. The PCB board is then allowed to cool and solder joint will be hardened.

See the working of Wave soldering machine

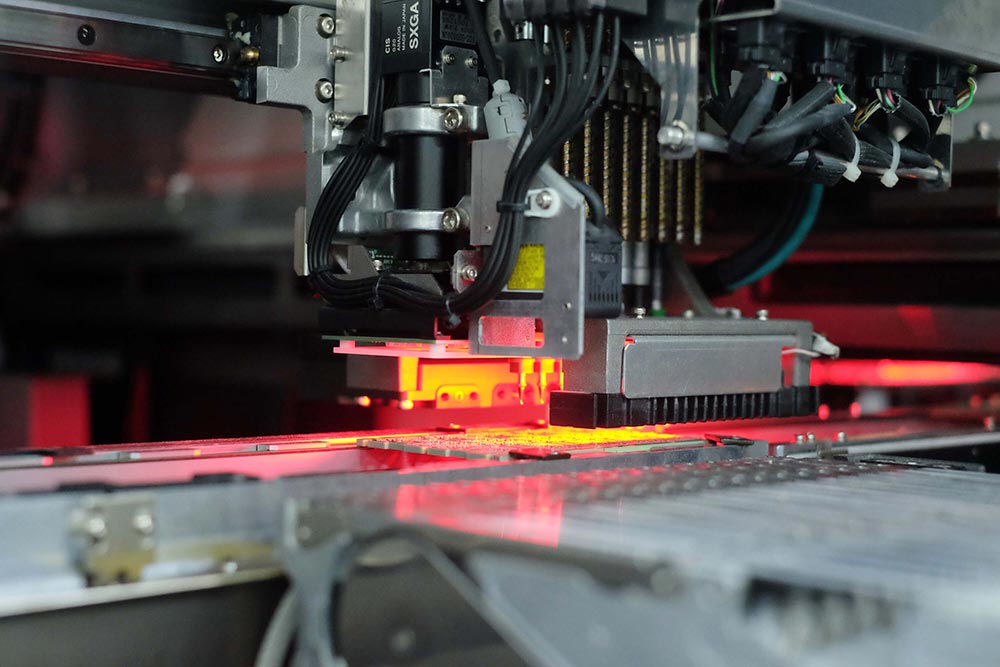

Automated Optical inspection:

AOI machine an automatic is used by PCB manufacturers in non contact PCB testing. This machine is equipped with a camera which is operated by the machine to scan PCBs. This machine will generate 2D images which is then used to compare between a good board and board under inspection. Along with that AOI machine measures and collects multitude of data points such as height and orientation of the components, board dimensions etc. These data points will help to detect problems such as improper soldering, component misalignment, solder bridges etc. Some AOI machines also generates 3D images of the boards which will help to detect 99% of the faults in it.

See the working of AOI machine

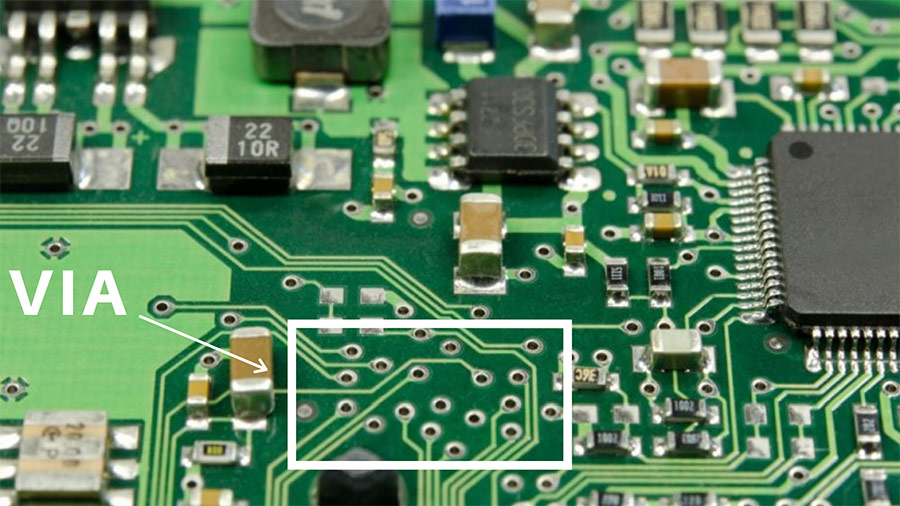

X-Ray machine:

AOI machine will help manufacturers to identify the faults that is external to the PCB board. However it is also highly possible for faults to occur internally in the PCB manufacturing process especially if it is a multi layered PCBs. X-ray machines will come in handy to visualize the internal structure and the faults that are not visible externally.

These are some of the PCBA machines that many modern manufacturers use to produce a high quality PCB board. PCBgogo makes use of all the above machine in their PCB manufacturing process and as a result they produce superior quality PCBs. Check out their website to know about their manufacturing capabilities and pricing.